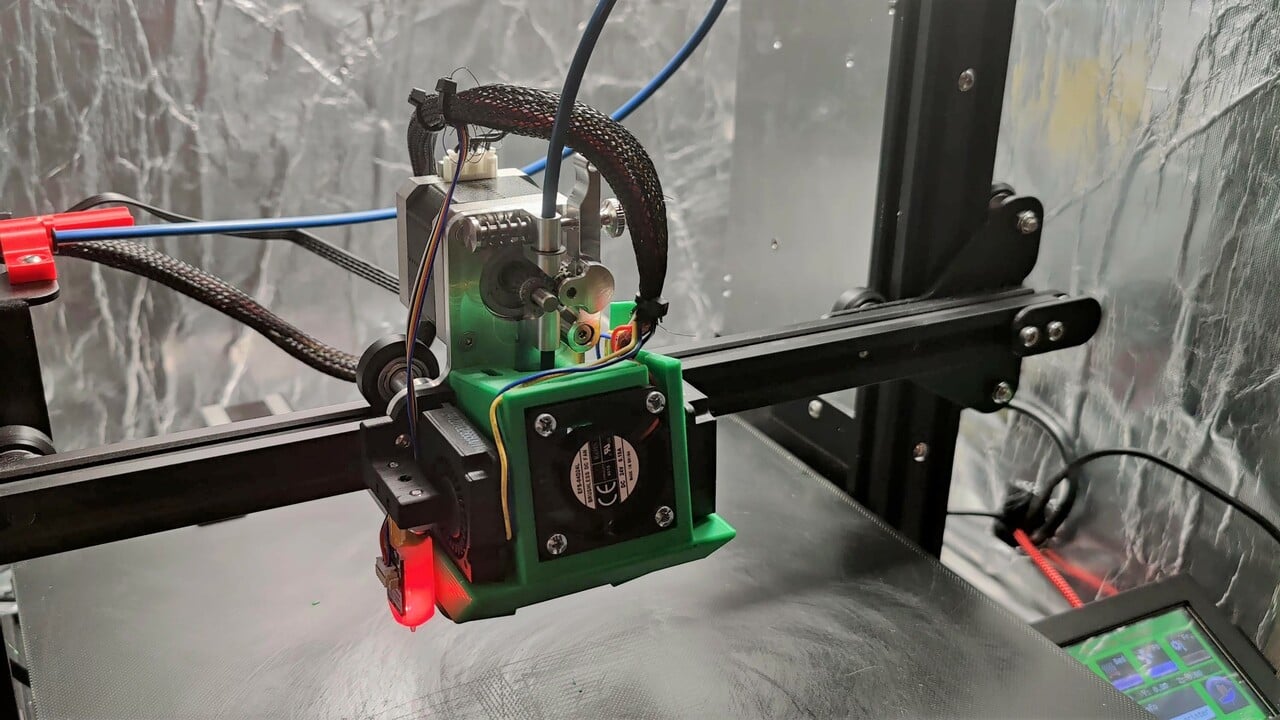

I disassembled the hotend, cut the PTFE tube and re-installed everything. Creality Ender 6 Review: Semi-Enclosed Core XY 3D Printer 1 This issue was caused by an incorrectly tightened nozzle and a PTFE tube which was not touching the nozzle, leaving a small section where filament could get stuck.

I removed the silicone cover only to be greeted by a big piece of white molten filament around the nozzle and heating block. I discovered this after the first 3D Benchy which was showing inconsistent extrusion. I need to mention that my stock hotend was not properly assembled and it already came with a partial clog. Paired with Klipper, the Ender 6 will probably be able to print much faster than the stock setup with a minimal investment. I will install an aftermarket hotend soon, to benefit from better heat break performance and higher flow rate. If you print at a higher temperature for longer periods of time the PTFE tube inside the hotend will start to degreade and release harmful fumes.įortunately, there are a lot of aftermarket hotends like the NF-Smart or the NF-Zone, out there which can improve the Ender 6 performance and eliminate headache in the future. With this hotend, the printing temperatures are limited to around ~240C for the hotend. It works, and it’s not as terrible as other hotends I’ve seen but this would be the first hardware upgrade I would do to the Ender 6.

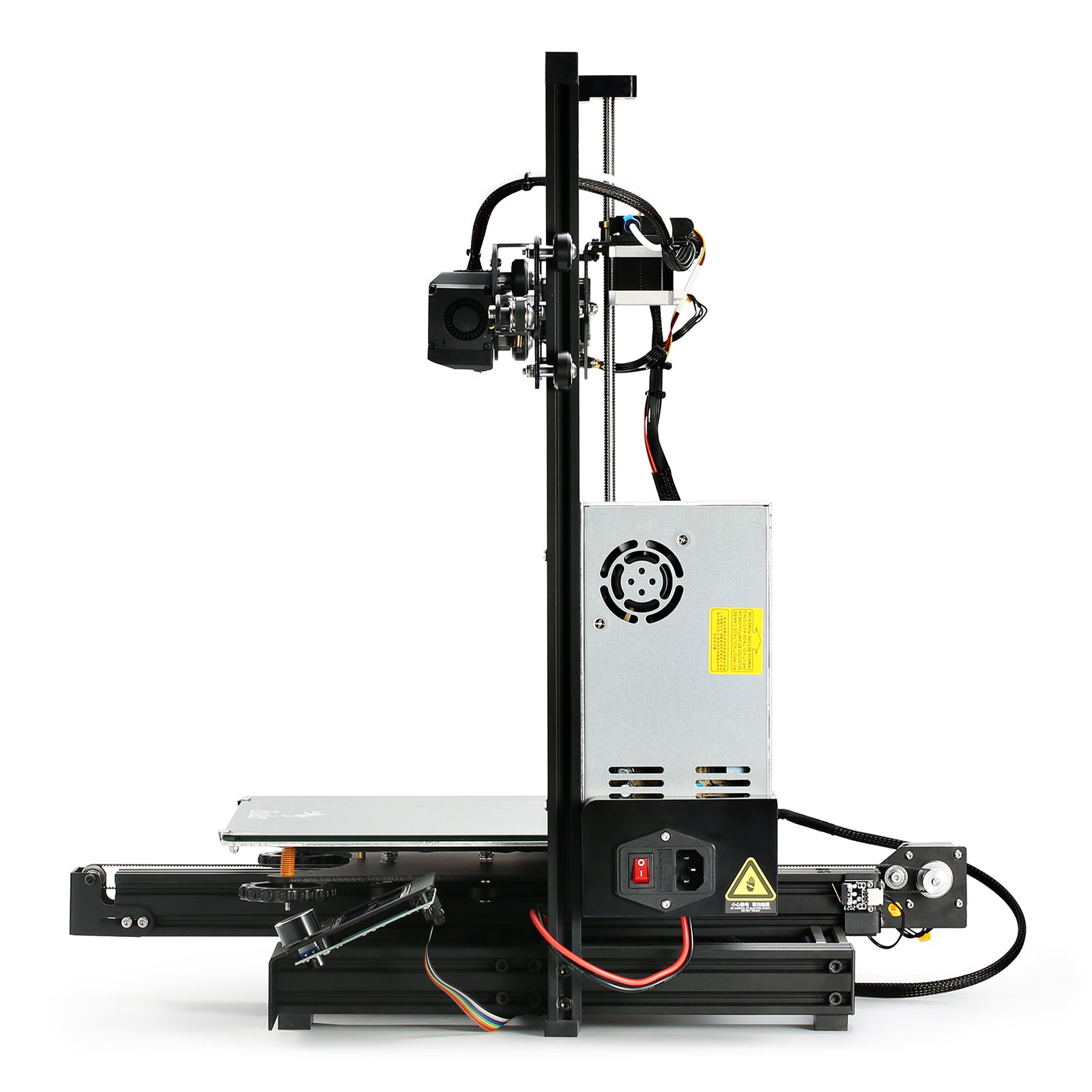

It’s the same old Creality style hotend used in the Ender lineup, which has a PTFE tube running right to the nozzle. I’m not that surprised to see that the Ender 6 hotend has the same generic Creality setup like other machines. There’s also the possibility of converting the Ender 6 to linear rails, but this adds to the cost of the machine and I’m not sure if it will improve the print quality significantly to make it worthwhile.

0 kommentar(er)

0 kommentar(er)